Lowering the Cost to Deliver Energy

Improving Well Productivity ▸

Data-Driven Frac Design Solutions

Liberty’s cutting-edge digital technologies have been major drivers of the doubling of average shale well production since our founding. Liberty’s leading engineers and geoscientists use our Spiral Up workflow to continue driving well productivity improvements. This workflow combines our customers’ data and knowledge with Liberty’s statistical and modeling tools for economic optimization.

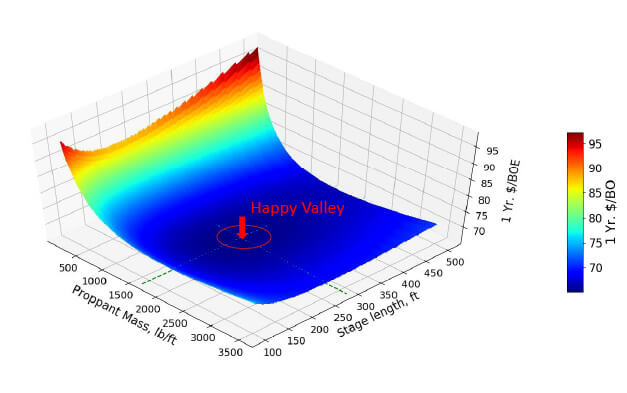

Fraconomics ▸

Lowering the cost of producing a barrel of oil

Fraconomics is Liberty’s multi-variate analysis (MVA) tool that uses data from FracTrends to identify completion parameters that independently impact production. This tool can then quantify the economic impacts of altering proppant mass per foot, frac stage length, injection rate, and more, to find the optimal completions strategy.

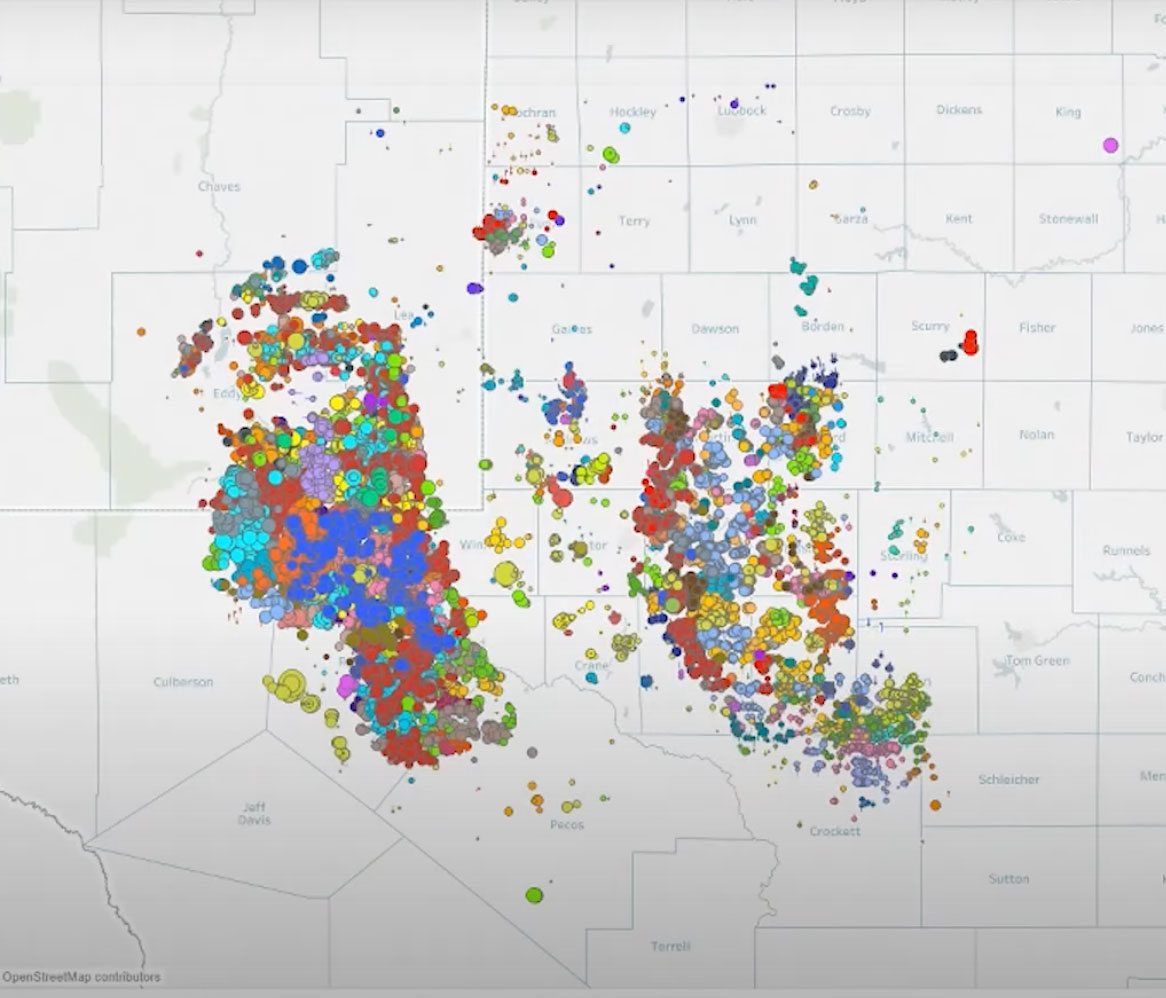

FracTrends Database ▸

A thorough repository of well data optimizing trend identification and improving production.

Liberty has built and rigorously maintains a database of over 100,000 wells across all major North American shale basins and the Western Canadian Sedimentary Basin. Our proprietary FracTrends™ database, coupled with our expertise in advanced data analytics, delivers actionable value-creation opportunities for our customers.

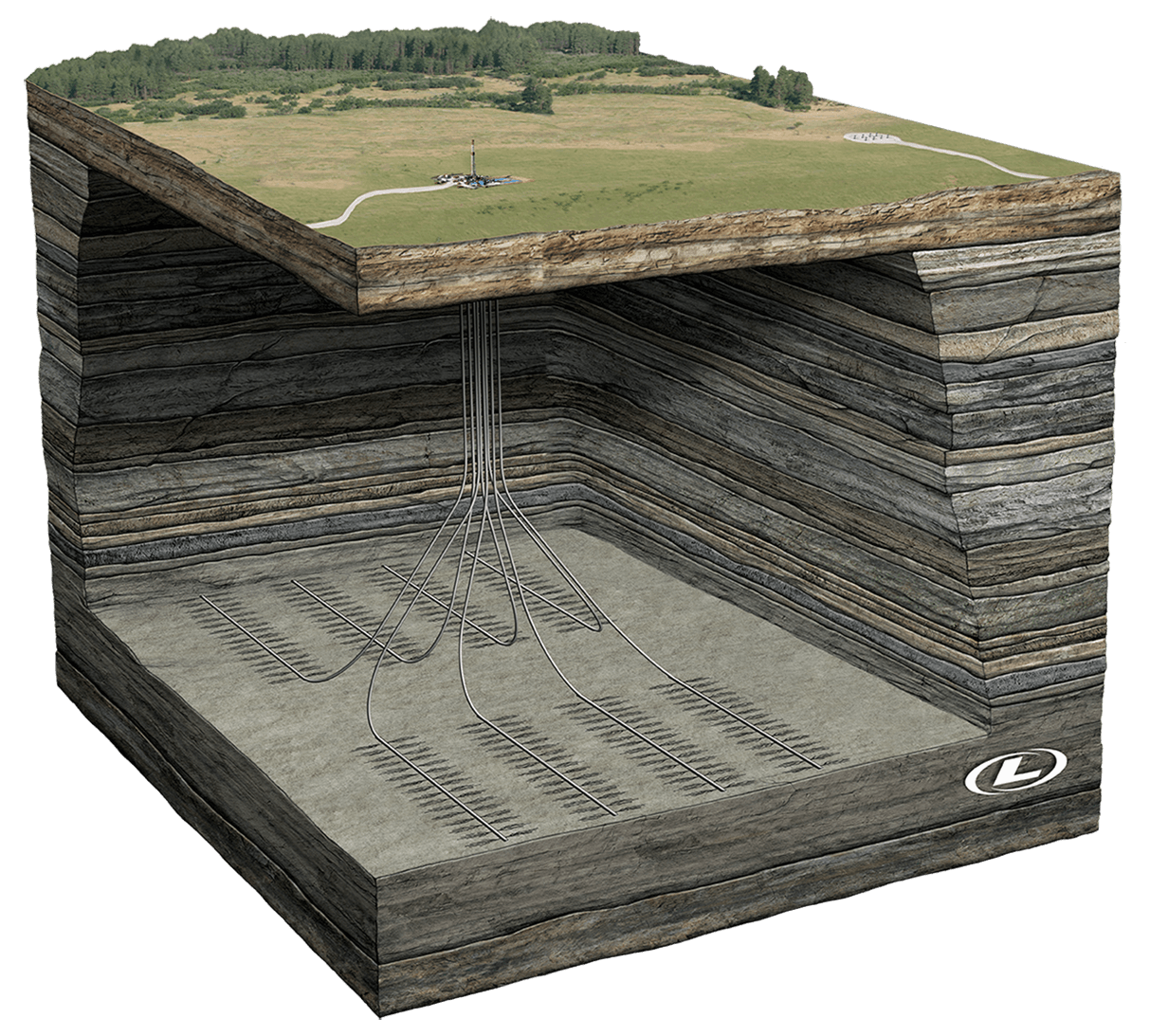

FracSense ▸

Deployable fiber optic cables provide detailed data to optimize hydraulic fracturing completions and well spacing.

The high-resolution data captured by FracSense provides per-stage information that significantly shortens operators’ learning curve for actionable change. FracSense measurements provide per-stage information about fracture azimuth, stage spacing coverage, and perforation cluster design and their impact on cluster efficiency.

The data also allows Liberty to help operators determine diversion techniques, alternate stage spacing, and fine-tune perforation designs for optimal cluster efficiency in real-time.

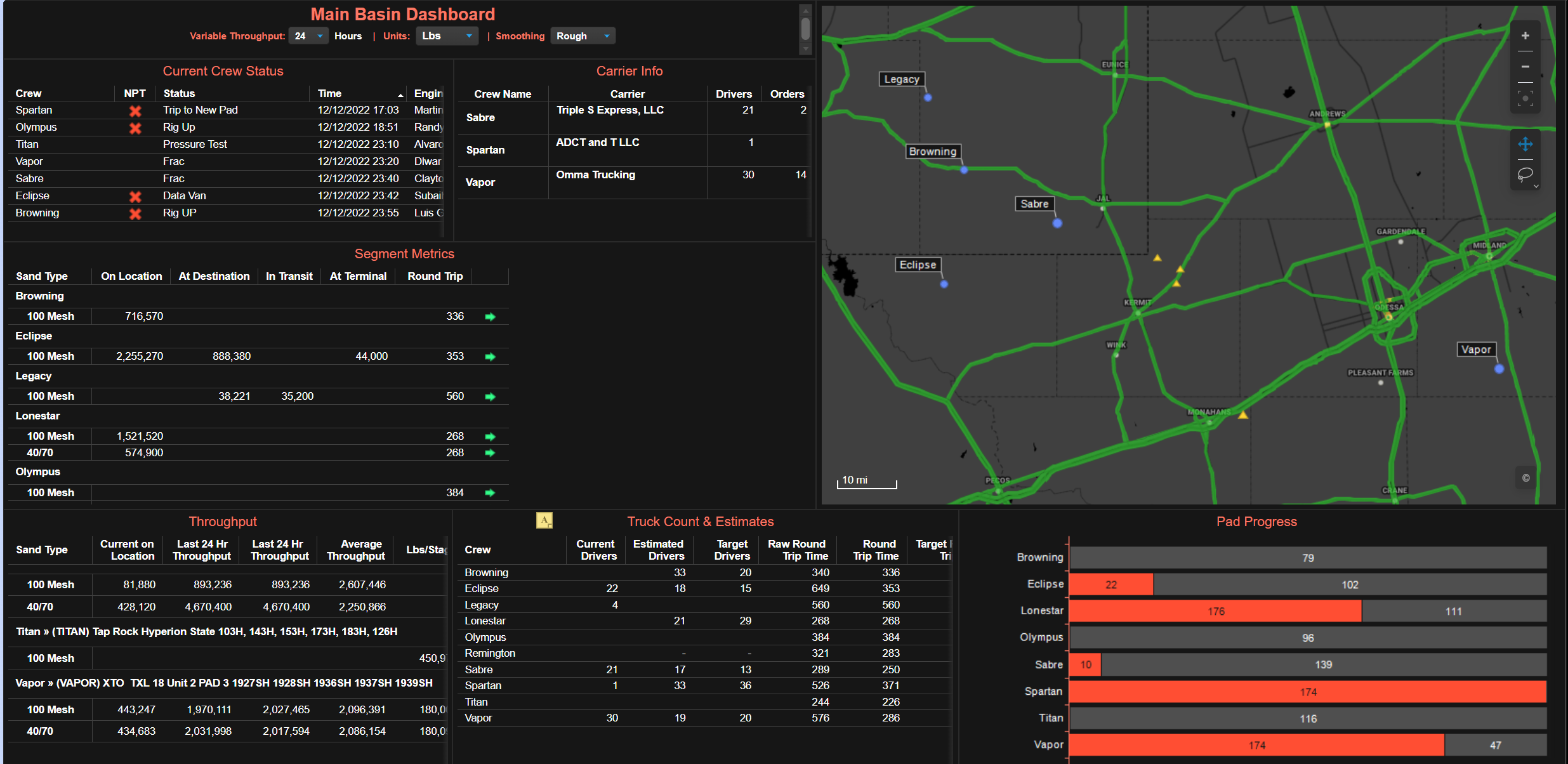

Inventory Management ▸

Sentinel Maximizes Efficiency

Sentinel leverages real-time field data that includes live inventory and consumption information for proppant, chemicals, and LPI CNG to ensure that each location is provided with the optimal quantity of products to support Liberty’s operations.

Data-Informed Flexibility

Sentinel is an advanced platform that uses real-time data from each frac location to accurately forecast on-site proppant volumes for the next 24 hours. This data includes current inventory and consumption rate trends as well as human and environmental variables including truck count, truck locations, loading facility wait times, traffic, and weather conditions. With this information, our central dispatch team can reallocate trucks as needed, adjusting pick-up locations, or adding drivers to create an optimal regional plan.

Chemistry ▸

Pioneering frac fluid chemistry

Liberty has been a pioneer in driving frac fluid chemistry forward since our founding. We have focused on the twin goals of increasing production efficiency and reducing the usage of frac chemicals.

We are always looking for ways to develop and use ever-greener chemicals and are proud that we have reduced the number and volume of chemicals needed to make top-performing frac fluids.

GreenSelect Program ▸

Liberty’s GreenSelect program uses the Global Harmonized System (GHS) as developed by the United Nations and adopted by OSHA to track health, physical, and environmental hazards. This helps inform our team’s decisions about the best next-generation chemistry, ensuring each new product has less impact than the previous one. We are transitioning to dry chemical additives whenever feasible, replacing the older method of using mineral oil as a carrier fluid for chemicals, further reducing our environmental impact.

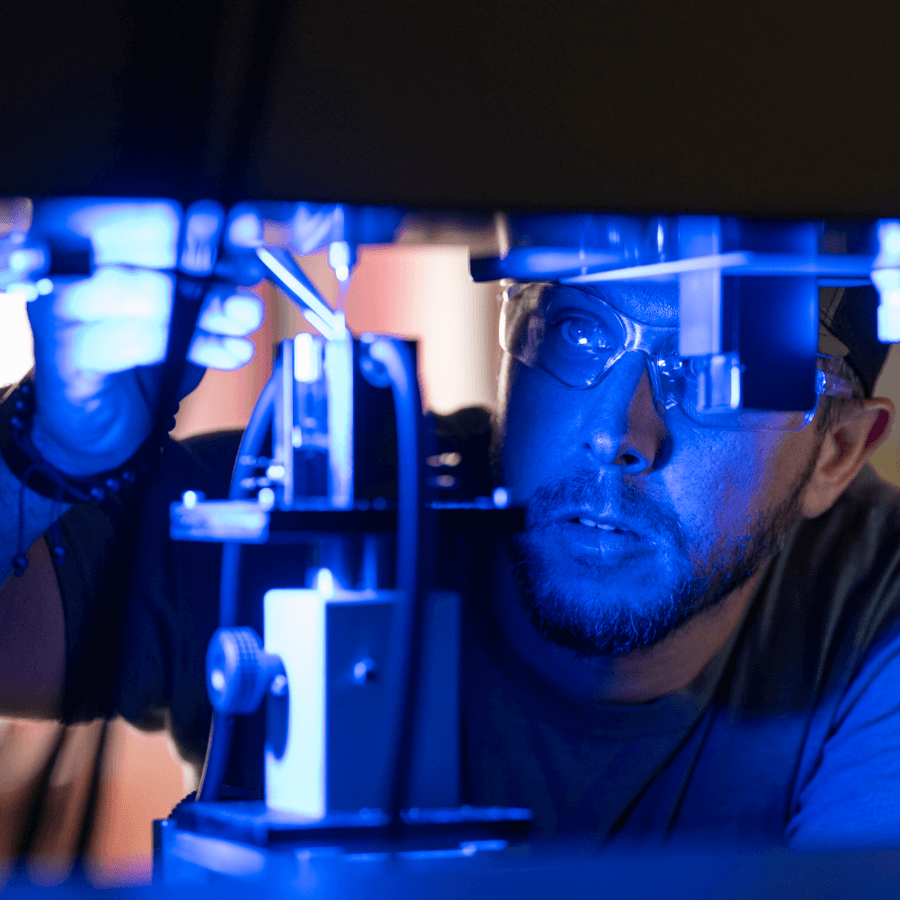

Proppant Testing & Analysis ▸

Custom Solutions by Job

There is no frac industry service provider with a deeper understanding of proppant selection. Liberty is the only provider that consistently measures what our customers obtain in terms of an effective conductivity pathway for decades of oil and gas production. We measure proppant pack conductivity for all the types of proppants we pump and measure regained proppant pack permeability for all our fluid types.