Industry-Leading Pumpdown Perforating

Prioritizing Excellence ▸

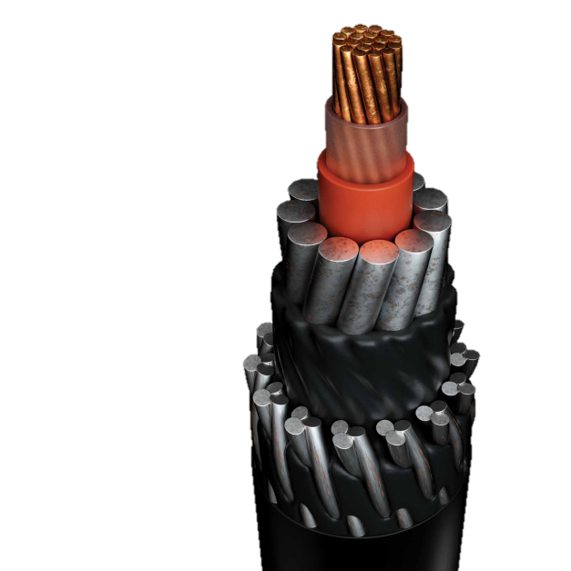

Wireline Services

At Liberty Wireline, our philosophy is centered on achieving excellence. Our highly skilled and knowledgeable crews utilize top-tier pump-down perforating equipment, raising the bar for safety, efficiency, and reliability.

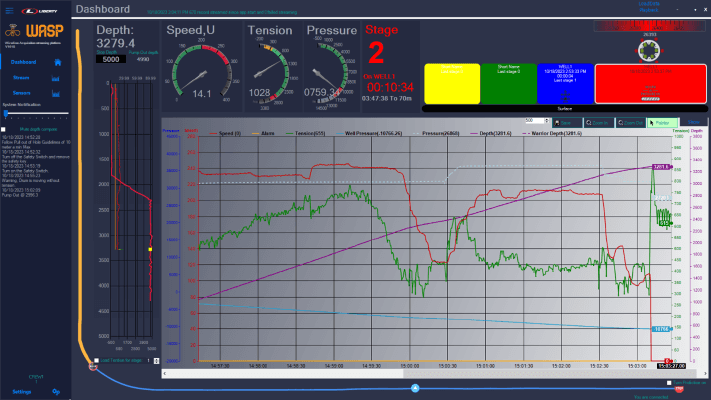

Real-time data for informed decision-making

Liberty Wireline services come equipped with proprietary business systems to enhance operations. Information is stored in the cloud, supporting real-time connectivity with other business systems. The customer experience includes real-time data streaming and detailed post-job summaries.

digiWire ▸

Electric Wireline

Designed to be an integral part of our digiTechnologies, the digiWire electric wireline unit is fully compatible with both digiFrac and digiPrime pumps. These units provide ESG benefits with improved reliability and emissions reduction. With precise electronics control, digiWire paves the way for automating the pump down operations.

Hybrid Wireline Unit

Liberty’s hybrid wireline unit incorporates an integrated electrical power module option and operates on a 480V, 3-phase power supply, eliminating the need for diesel consumption during operation. In case of power loss or unavailability, it can effortlessly switch back to diesel mode, ensuring uninterrupted performance. This hybrid unit offers flexibility and sustainability for a variety of applications.

Red on Red ▸

Optimize Further With Liberty Frac

Pairing Liberty Frac with Liberty Wireline brings a wealth of knowledge and experience with a common goal of optimizing operations. Making decisions on-pad has a shared priority, to keep pumps in gear. Paired Frac and Wireline fleets see higher pumping hours per day, setting industry records in multiple basins. Non-Liberty paired fleets have 55% more wireline-related NPT than Liberty-paired (Red-on-Red) fleets.

FracSense ▸

Fiber Optic Sensing & Fracture Monitoring

Liberty FracSense technology utilizes deployable fiber optic cables to capture high-resolution data to optimize hydraulic fracturing completions and well spacing. FracSense measurements provide per-stage information about fracture azimuth, stage spacing coverage, and perforation cluster design and their impact on cluster efficiency.

Resources ▸

Felix Dorante, Liberty’s Wireline Manager, introduces our wireline services in this short video. Download the Wireline data sheet.